VRC-2 Features

VRC-2 Features

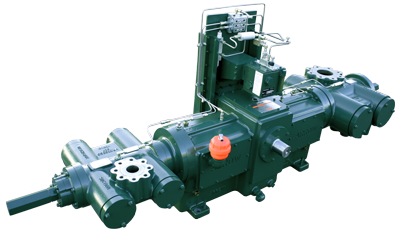

The Arrow VRC-2 gas compressor is a two-throw separable reciprocating gas compressor. The horizontally opposed cylinders are accurately balanced for smooth running and long lasting durability at 1800 RPM.

Unlike many other reciprocating gas compressors, the VRC-2 has a unique three-throw crankshaft configuration that eliminates opposing cylinder off-set and the vibration associated with traditional designs. The absolute alignment of opposing cylinders provides perfectly balanced weight distribution and symmetry. The elimination of vibration associated with horizontal couple inherent with traditional designs, along with state-of-the-art engineering design and rugged construction, make the VRC-2 a truly balanced, high performance, durable compressor specifically designed for continuous operation at high speed. The 1800 RPM speed design, 150 horsepower rating and 14,000 pound combined rod load capability make the VRC-2 a perfect fit for direct coupling with today’s higher speed gas engines.

VRC-2 Packaging

The Arrow VRC-2 can be packaged for single, two, three or four stage applications with double acting and steeple cylinder sizes from 2¼” to 8”. Cylinders are air cooled which reduces packaging and maintenance costs. As a standard feature, cylinders have a variable volume clearance pocket for flexibility and adjustment to allow accurate fits for changing field conditions.

VRC-2 Compressor Frame Specifications

| VRC-2 Gas Compressor Specifications | |||

|---|---|---|---|

| Rated Horsepower | 150 hp | 93 kW | |

| Maximum Speed RPM | 1800 RPM | ||

| Number Of Throws | 2 | ||

| Rod Load - Tension | 7000 lb | 3175 kg | |

| Rod Load - Compression | 7000 lb | 3175 kg | |

| Rod Load - Combined | 14,000 lb | 6350 kg | |

| Stroke | 3 in | 76.2 mm | |

| Piston Speed | 900 ft/min | 4.57 m/s | |

| Crankshaft Diameter | 2.50 in | 63.50 mm | |

| Crankshaft Height To Cl | 12.75 in | 323.85 mm | |

| Overall Length w/cyls. | 22.5 in | .57M | |

| Overall Width w/cyls. | 95 in | 2.41 M | |

| Unit Weight w/cyls. | 1700 lb | 771 kg | |

| Oil Pump Capacity | 4 gpm | 15 lpm | |

| Oil Heat Rejection | 3750 btu | 945 kcal/hr | |

| Oil Sump Capacity | 4 gal | 15 L | |

| Components | |||

| Crankshaft Main Bearing Diameter In (mm) | 3.346 in | 84.988 mm | |

| Crankpin Diameter | 2.447 in | 62.154 mm | |

| Main Bearing Type | Spherical Roller | ||

| Connecting Rod Length Cl-Cl | 7.375 in | 187.325 mm | |

| Connecting Rod Bearing Width (Single) | 1.604 in | 40.742 mm | |

| Connecting Rod Bushing Width (Single) | 1.750 in | 44.45 mm | |

| Connecting Rod Bolts (Single) | (Four) 1/2” | ||

| Connecting Rod Bearing Width (Double) | 0.802 in | 20.371 mm | |

| Connecting Rod Bushing Width (Double) | 0.875 in | 22.225 mm | |

| Connecting Rod Bolts (Double) | (Two) 1/2” | ||

| Crosshead Surface | 5.25 in x 3.5 in | 133.35 mm x 88.90 mm | |

| Floating Crosshead Pin Diam. | 2.235 in | 56.769 mm | |

| Piston Rod Diameter | 1.125 in | 28.575 mm | |

| Materials | |||

| Frame | Class 40 Gray Iron) | ||

| Crankshaft | Forging With Induction Hardened Journals | ||

| Connecting Rods | Forging | ||

| Connecting Rod Bearings | Tri-metal | ||

| Crossheads | 65-45-12 Ductile Iron | ||

| Crosshead Pins | SAE 8620 Carburized | ||

| Crosshead Pin Bushings | SAE 660 Bronze | ||

| Piston Rods | SAE 4140 - Induction Hardened | ||

| Packing Rings | Carbon Filled Teflon w/ Cast Iron Backup Rings | ||

| Pistons | Cast Iron Or Aluminum | ||

| Piston Rings | Carbon Filled Teflon | ||

| Cylinders | 80-55-06 Ductile Iron | ||